and Detail Drawings

Wales

England

- Offices

- Shops / Commercial

- Industrial Buildings

- Storage / Assembly Buildings

- Other Non-Residential

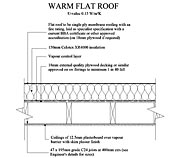

Flat Roof - Components

Components of a Flat Roof

A flat roof is a multi-layer construction typically comprising of the following elements:

- Waterproof membrane with a protective covering - this should prevent water reaching the roof structure and the room below.

- Thermal insulation – ensures thermal comfort is maintained inside the building and often provides support for the waterproofing membrane (warm roof).

- Roof deck - provides a base for the waterproof membrane or the insulation.

- Vapour control layer - helps reduce the risk of condensation.

- Load bearing supportive structure - transmits the weight of the roof and any loads acting on it onto the loadbearing walls. In domestic buildings, the structure is usually in the form of timber joists although it may be concrete or even steel structures can be used.

- Ceiling - usually plasterboard.

- Outlets and gutters.

The choice of materials for the different components will depend upon type of roof, whether cold deck, warm deck or inverted (see below). Components must be compatible with each other as some components, for example, may react badly when in contact with other materials.

Roof Covering Waterproofing System

The covering for a flat roof will normally comprise of one or more layers of roofing sheet material.

This material should be of adequate durability and remain weather tight, resisting the action of rain, snow and ice, and preventing any water entering the building.

The designer will need to ensure the roof covering is robust enough to handle all the dead, imposed and wind loads, and UV solar radiation.

There are various types of roof coverings including:

- Built–up reinforced bitumen membrane (often named ‘felt’).

- Mastic asphalt roofing.

- Single-ply roofing systems.

- Green roofs (intensive and extensive).

- Metal sheet roofing, including zinc, copper and lead.

Priming decks and substrates

In order to achieve a good key, ensure a longer lasting watertight finish or to stabilise and seal porous substrates, primers can be applied before applying the waterproofing covering.

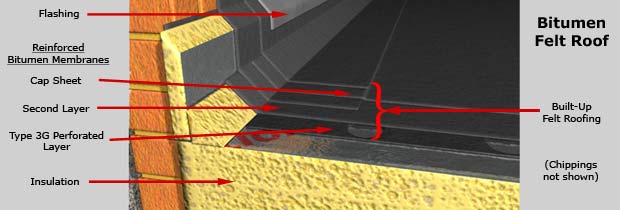

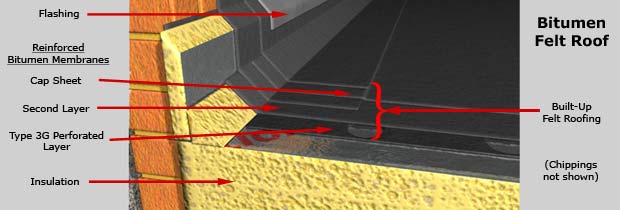

Built up bituminous membranes (felt)

Built up bituminous membranes are probably the most economical and common form of roof covering material for domestic flat roofs. They can be used on timber, metal and concrete decks.

Today’s high performance felts are reinforced with polyester or glass or a mixture of the two, and are coated and impregnated with bitumen.

High performance felts are supplied in rolls and can be laid in two layers bonded together with hot bitumen. The multiple layering reduces the risk of failure, as any damage in one layer will usually be covered by the next layer.

High performance felts are often referred to by the additive used in their manufacture:

- AAP (atactic –polypropoylene) – normally used for torch-on technique.

- SBS (stryrene – butadiene- styrene) - normally used for pour-and-roll application.

Roofing felt should conform to the requirements of BS EN 13707:

- Flexible sheets for waterproofing - reinforced bitumen sheets for roof waterproofing.

The most common types of felts are described below:

Type 5

- Class 5B or 5U felt can be used for the base or intermediate layer.

- Class 5B can only be used for the top layer when provided with surface protection.

- Class 5E can be used for the top layer and is already provided with a surface protection in the form of mineral granules.

Type 3

- Type 3 glass-fibre-based felts are less durable and are only suitable for intermediate layers, but can be used as a base layer when partially bonded.

- Type 3G is perforated and can be used as a venting base layer to give a partial bond.

Type 1 traditional organic woven rag based felts have been removed from the British standards and should not be used.

Laying the felt

All felts should be laid in the following manner:

- with staggered joints.

- with side laps of 50mm minimum and end laps of 75mm minimum.

- the sheets should be laid, starting from the bottom, laying progressively up the slope of the roof so that water will not run into the joints of the laps.

- a vapour control layer is required beneath the insulation.

Torch-on membranes

Torch-on bitumen felts are pre-coated with bitumen. The top layer is usually polyester based and the underlay may be polyester reinforced or glass fibre based.

Application

- Melt the bitumen by heating on the underside of the membrane from a gas torch.

- Roll the membrane out on to the substrate where it can form a bond.

The torch-on technique is very reliant on good workmanship and is unsuitable for laying on to timber decks or flammable materials.

Traditional ‘pour and roll’ method of bituminous flat roofing

The pour and roll method is the more traditional way of laying the roofing membrane.

Application

- Heat the bitumen to over 200ºC.

- Pour the heated bitumen onto the substrate in front of the felt.

- Roll the felt onto the hot bitumen.

Full or partial bonding

The felt membrane can either be partially or fully bonded to the substrate. The pour and roll and torch-on technique will provide a full bond. This has the advantage of providing a high level of resistance to wind uplift and ensuring no flow path for water is provided under the membrane which could cause moisture to become trapped and blister the membrane.

However, a full bond will not accommodate thermal movement between the membrane and the substrate which could possibly cause the membrane to split or crack.

Therefore, the first waterproofing layer is usually partially bonded. This can be achieved by using one of the following methods:

- Providing a perforated underfelt, for example Type 3G, laid loose over the decking or over rigid insulation boards before applying the bitumen.

- Pouring the hot bitumen in a series of strips, before rolling the felt into it.

- Mechanically fixing the felt by nailing it to the substrate using 20mm galvanized clout nails at approximately 150mm centres in both directions. This is the usual method of fixing when laying the felt on to timber board substrates.

Subsequent layers of felt membrane should always be fully bonded.

Partial bonding will allow the waterproofing layer to be isolated from the substrate so that it accommodates differential movement that might otherwise cause it to split.

However, the reduced contact between membrane and substrate in a partial bond will mean there is a greater potential for wind uplift.

Add To Basket

Includes DXF,

DWG & JPG

This is just a Small Sample from our Drawing Library.

Cold applied bitumen felt roofing

Cold applied membranes are a safer alternative to using hot bitumen and gas torches, but are only really suitable for small jobs such as small repairs or shed roofs.

Cold applied bitumen membranes usually comprise of fibre or glass fibre and bitumen and are bonded with a suitable cold adhesive of brushable consistency.

Membranes are applied in one, two or three layers on concrete, asphalt, metal and timber decks, although the manufacturer's details should be checked to ensure compatibility. Absorbent or dusty surfaces should first be primed with a suitable proprietary roof primer.

Application

- The deck must be free from any dust, dirt, moisture etc and may need to be primed with special primer.

- The adhesive is applied evenly onto the roof surface.

- The roofing felt is unrolled onto the adhesive.

- All laps are sealed with the cold adhesive.

- Pressure contact may be required to ensure full adhesion.

- Laps should be a minimum of 75mm and sealed or heat welded.

- Joints should be staggered.

Self Adhesive Membrane

Self-adhesive membranes are bituminous compounds with a polyester and/or fiberglass reinforcement with the adhesive already on the underside of the membrane.

Normally laid in two layers, they can be applied without using hot gas torches and can be laid with only basic skills.

Application

- The deck must be free from any dust, dirt, moisture etc and may need to be primed with special felt primer.

- The backing paper should be peeled off and the membrane stuck to the prepared deck.

- Pressure contact is required to ensure full adhesion.

- Laps should be a minimum of 75mm and sealed or heat welded.

- Joints should be staggered.

Self adhesive membranes are ideal for the diy market for application on small roofs, garages, sheds. Self adhesive membranes should not be laid in cold weather.

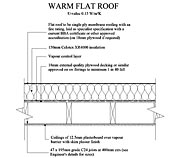

Single Ply Roofing

A single-ply roofing membrane is suitable for use on timber, metal and concrete decks; although compatibility with other materials should always be checked with the with manufacturer.

Single-ply membranes are mostly used on large commercial buildings. They can be laid in a single sheet and allow more choice in roof design.

Today’s single-ply membranes are strong, flexible and durable and have a typical life span of about 20 years but are often known to last longer.

However, there are no national standards for single-ply membranes and installation should be in strict accordance the manufacturer's details, the British Board of Agreement (BBA) certificate or WIMLAS certificate.

Single-ply membranes are made from synthetic polymers or rubber often reinforced with glass fibre or polyester. They can be categorised as either thermoplastic or elastomeric.

Add To Basket

Includes DXF,

DWG & JPG

Thermoplastic

Thermoplastic membranes include PVC (polyvinyl chloride). These can soften when heated, allowing them to be hot welded.

However, thermoplastic membranes can be susceptible to damage when in contact with other chemicals including bitumen, therefore compatibility with other materials should always be checked.

Elastomeric

Elastomeric membranes include Butyl rubber and EPDM. Common in the UK, these membranes are less sensitive to temperature than thermoplastic and provide good weather resistance.

Installation

Single-ply membranes can be laid as one entire piece with the eaves and verge already formed in the factory or in rolls which are laid in strips. The laps can then be joined by heat welding or proprietary solvent to melt and fuse laps together or adhesive tapes, depending on the type of membrane.

Single-ply sheets should always be laid starting from the lowest point of the roof so that rainwater is shed over all lapped joints rather seeping between the sheets.

Insulation manufacturers often recommend an additional 12mm plywood to be provided between the insulation and the membrane.

Fixing to the substrate

Single-ply membranes can be attached to the substrate using any of the following methods;

- Mechanical fixing

This is the most common type of fixing.

The membrane is loosely laid and mechanically fixed through the insulation to the substrate using proprietary metal or plastic screw fastenings.

Single-plys can also be mechanically fixed by heat or chemically welding special membrane-coated discs or strips to the deck.

- Adhesive bonding

Adhesive bonding provides a full bond to the insulation or deck. The membrane is rolled into a proprietary adhesive applied directly to the substrate. A few single-plys come with the adhesive already bonded to the membrane.

- Bitumen bonding

Some single-ply membranes are fully compatible with bitumen and can be rolled directly into hot bitumen poured onto the substrate.

- Loose laid and ballasted

This method of fixing is suitable for warm and inverted roofs.

In a warm roof design, the single-ply membrane is laid loose over the insulation. The ballast, in the form of round washed stones, paving slabs or soil and planting (green roof systems), is then laid over the membrane. The weight of the ballast holds the membrane in place.

A polymeric layer should always be provided between the membrane and the ballast to protect the membrane from abrasion.

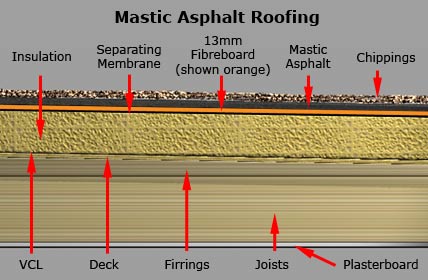

Mastic Asphalt

A mastic asphalt roof gives a seamless covering and can be used on timber, metal and concrete decks. It is not as common as built-up felt for small domestic roofs, even though it is known to be more durable and generally performs better as a waterproofing material.

Mastic asphalt is a mixture of asphalt, bitumen and aggregates. Asphalt occurs naturally in asphalt lakes and rock but is more commonly obtained from the process of refining crude oil. Modern mastic asphalt products incorporate polymer which enables an extremely durable and flexible material to be produced.

Mastic asphalt should be laid to the recommendations of BS 8218 Code of Practice for mastic asphalt roofing.

Mastic asphalt is delivered on to the site as solidified blocks and is re-melted before applying to the deck. The number of coats should be appropriate to the waterproofing requirements and anticipated traffic, but will usually be two coats, a minimum 20mm thick over an isolating membrane of type 4A black sheathing felt to BS747.

The sheathing felt should be laid loose with 50mm overlaps and will protect the mastic asphalt covering from damage caused by thermal movement of the deck. Insulation manufacturers often specify an additional 13mm fibreboard over the insulation.

The effects of solar radiation on the mastic asphalt can be reduced by rubbing sand into the surface of the topcoat breaking up any build-up of bitumen.

Liquid Applied Coatings

Liquid applied systems are ideal for diy projects and carrying out repairs. They provide a seamless finish with a full bond to substrate and are often a practical option for curved roofs.

Normally, bitumen-based liquid applied systems are emulsified flexible polyurethane systems or synthetic rubber systems. Generic types are defined as ETAs.

Most liquid applied systems are cold-applied, although hot-applied systems are available.

Application

- Apply a primer on a clean dry surface.

- Brush, roll or spray the liquid applied membrane on to the substrate in three or four layers.

- Some form of reinforcement fabric(scrim) to deal with the tensile stresses, either glass fibre or polyester fleece, should be laid loose before the second coat is applied (some types are already fibre-filled and do not require additional reinforcement).

A high standard of workmanship is essential.

No standards exist for this type of system and the manufacturer's guidance should always be followed. Compatibility with insulation, deck etc must be checked. Most types of liquid-applied membranes should not be applied below 5°C.

However, liquid applied membranes do not offer the same durability as some other coverings, with a life expectancy of only around 10 years.

Sheet Metal Roofing

Sheet metal materials commonly used for flat roof covering include aluminium, copper, lead, stainless steel, terne coated stainless steel (TCSS) and zinc.

They are usually in the form of preformed panels with the sheet metal already bonded to a plywood background. The sheets are laid over the supporting structure on a slip layer of polythene to accommodate movement.

Copper is a particularly durable choice of metal but can be expensive. Lead is a more common choice as it is less expensive and can still last 100 years or more.

Sheet membrane should not be laid in temperatures of 5°C or below.

Lead

Lead is specified in codes from Code 3 to 8. The higher the code number, the thicker and more durable the lead will be. Flat roofs will require a minimum of Code 6 lead. Expansion joints known as ‘rolls’ and ‘drips’ must be formed in lead sheeting.

Service Perforations

Air leakage and water ingress should be prevented by sealing around pipes or ducts passing through the roof, for example around soil and vent pipes or roof ventilators. The roofing membrane should be taken up around the pipe or duct and provided with a cover flashing.

Any services through the vapour control layer must also be sealed.

Flat Roof - Components

Components of a Flat Roof

A flat roof is a multi-layer construction typically comprising of the following elements:

- Waterproof membrane with a protective covering - this should prevent water reaching the roof structure and the room below.

- Thermal insulation – ensures thermal comfort is maintained inside the building and often provides support for the waterproofing membrane (warm roof).

- Roof deck - provides a base for the waterproof membrane or the insulation.

- Vapour control layer - helps reduce the risk of condensation.

- Load bearing supportive structure - transmits the weight of the roof and any loads acting on it onto the loadbearing walls. In domestic buildings, the structure is usually in the form of timber joists although it may be concrete or even steel structures can be used.

- Ceiling - usually plasterboard.

- Outlets and gutters.

The choice of materials for the different components will depend upon type of roof, whether cold deck, warm deck or inverted (see below). Components must be compatible with each other as some components, for example, may react badly when in contact with other materials.

Roof Covering Waterproofing System

The covering for a flat roof will normally comprise of one or more layers of roofing sheet material.

This material should be of adequate durability and should remain weather tight, resisting the action of rain, snow and ice, and preventing any water entering the building.

The designer will need to ensure the roof covering is robust enough to handle all the dead, imposed and wind loads, and UV solar radiation.

There are various types of roof coverings including:

- Built–up reinforced bitumen membrane (often named ‘felt’).

- Mastic asphalt roofing.

- Single-ply roofing systems.

- Green roofs (intensive and extensive).

- Metal sheet roofing, including zinc, copper and lead.

Priming decks and substrates

In order to achieve a good key, ensure a longer lasting watertight finish or to stabilise and seal porous substrates, primers can be applied before applying the waterproofing covering.

Built up bituminous membranes (felt)

Built up bituminous membranes are probably the most economical and common form of roof covering material for domestic flat roofs. They can be used on timber, metal and concrete decks.

Today’s high performance felts are reinforced with polyester or glass or a mixture of the two, and are coated and impregnated with bitumen.

High performance felts are supplied in rolls and can be laid in two layers bonded together with hot bitumen. The multiple layering reduces the risk of failure as any damage in one layer will usually be covered by the next layer.

High performance felts are often referred to by the additive used in their manufacture:

- AAP (atactic –polypropoylene) – normally used for torch-on technique.

- SBS (stryrene – butadiene- styrene) - normally used for pour-and-roll application.

Roofing felt should conform to the requirements of BS EN 13707:

- Flexible sheets for waterproofing - reinforced bitumen sheets for roof waterproofing.

The most common types of felts are described below:

Type 5

- Class 5B or 5U felt can be used for the base or intermediate layer.

- Class 5B can only be used for the top layer when provided with surface protection.

- Class 5E can be used for the top layer and is already provided with a surface protection in the form of mineral granules.

Type 3

- Type 3 glass-fibre-based felts are less durable and are only suitable for intermediate layers, but can be used as a base layer when partially bonded.

- Type 3G is perforated and can be used as a venting base layer to give a partial bond.

Type 1 traditional organic woven rag based felts have been removed from the British standards and should not be used.

Laying the felt

All felts should be laid in the following manner:

- with staggered joints.

- with side laps of 50mm minimum and end laps of 75mm minimum.

- the sheets should be laid, starting from the bottom, laying progressively up the slope of the roof so that water will not run into the joints of the laps.

- a vapour control layer is required beneath the insulation.

Torch-on membranes

Torch-on bitumen felts are pre-coated with bitumen. The top layer is usually polyester based and the underlay may be polyester reinforced or glass fibre based.

Application

- Melt the bitumen by heating on the underside of the membrane from a gas torch.

- Roll membrane out on to the substrate where it can form a bond.

The torch-on technique is very reliant on good workmanship and is unsuitable for laying on to timber decks or flammable materials.

Traditional ‘pour and roll’ method of bituminous flat roofing

The pour and roll method is the more traditional way of laying the roofing membrane.

Application

- Heat the bitumen to over 200ºC.

- Pour the heated bitumen onto the substrate in front of the felt.

- Roll the felt onto the hot bitumen.

Full or partial bonding

The felt membrane can either be partially or fully bonded to the substrate. The pour and roll and torch on technique will provide a full bond. Tthis has the advantage of providing a high level of resistance to wind uplift and ensuring no flow path for water is provided under the membrane which could cause moisture to become trapped and blister the membrane.

However, a full bond will not accommodate thermal movement between the membrane and the substrate which could possibly cause the membrane to split or crack.

Therefore, the first waterproofing layer is usually partially bonded. This can be achieved by using one of the following methods:

- Providing a perforated underfelt, for example Type 3G, laid loose over the decking or over rigid insulation boards before applying the bitumen.

- Pouring the hot bitumen in a series of strips, before rolling the felt into it.

- Mechanically fixing the felt by nailing it to the substrate using 20mm galvanized clout nails at approximately 150mm centres in both directions. This is the usual method of fixing when laying the felt on to timber board substrates.

Subsequent layers of felt membrane should always be fully bonded.

Partial bonding will allow the waterproofing layer to be isolated from the substrate so that it accommodates differential movement that might otherwise cause it to split.

However, the reduced contact between membrane and substrate in a partial bond will mean there is a greater potential for wind uplift.

Add To Basket

Includes

DWG and Jpeg

Cold applied bitumen felt roofing

Cold applied membranes are a safer alternative to using hot bitumen and gas torches, but are only really suitable for small jobs such as small repairs or shed roofs.

Cold applied bitumen membranes usually comprise of fibre or glass fibre and bitumen and are bonded with a suitable cold adhesive of brushable consistency.

Membranes are applied in one, two or three layers on concrete, asphalt, metal and timber decks, although the manufacturer's details should be checked to ensure compatibility. Absorbent or dusty surfaces should first be primed with a suitable proprietary roof primer.

Application

- The deck must be free from any dust, dirt, moisture etc and may need to be primed with special primer.

- The adhesive is applied evenly onto the roof surface.

- The roofing felt is unrolled onto the adhesive.

- All laps are sealed with the cold adhesive.

- Pressure contact may be required to ensure full adhesion.

- Laps should be a minimum of 75mm and sealed or heat welded.

- Joints should be staggered.

Self Adhesive Membrane

Self-adhesive membranes are bituminous compounds with a polyester and/or fiberglass reinforcement with the adhesive already on the underside of the membrane.

Normally laid in two layers, they can be applied without using hot gas torches and can be laid with only basic skills.

Application

- The deck must be free from any dust, dirt, moisture etc and may need to be primed with special felt primer.

- The backing paper should be peeled off and the membrane stuck to the prepared deck.

- Pressure contact is required to ensure full adhesion.

- Laps should be a minimum of 75mm and sealed or heat welded.

- Joints should be staggered.

Self adhesive membranes are ideal for the diy market for application on small roofs, garages, sheds. Self adhesive membranes should not be laid in cold weather.

Single Ply Roofing

A single-ply roofing membrane is suitable for use on timber, metal and concrete decks; although compatibility with other materials should always be checked with the with manufacturer.

Single-ply membranes are mostly used on large commercial buildings. They can be laid in a single sheet and allow more choice in roof design.

Today’s single-ply membranes are strong, flexible and durable and have a typical life span of about 20 years but are often known to last longer.

However, there are no national standards for single-ply membranes and installation should be in strict accordance the manufacturer's details, the British Board of Agreement (BBA) certificate or WIMLAS certificate.

Single-ply membranes are made from synthetic polymers or rubber often reinforced with glass fibre or polyester. They can be categorised as either thermoplastic or elastomeric.

Add To Basket

Includes

DWG and Jpeg

Thermoplastic

Thermoplastic membranes include PVC (polyvinyl chloride). These can soften when heated, allowing them to be hot welded.

However, thermoplastic membranes can be susceptible to damage when in contact with other chemicals including bitumen, therefore compatibility with other materials should always be checked.

Elastomeric

Elastomeric membranes include Butyl rubber and EPDM. Common in the UK, these membranes are less sensitive to temperature than thermoplastic and provide good weather resistance.

Installation

Single-ply membranes can be laid as one entire piece with the eaves and verge already formed in the factory or in rolls which are laid in strips. The laps can then be joined by heat welding or proprietary solvent to melt and fuse laps together or adhesive tapes, depending on the type of membrane.

Single-ply sheets should always be laid starting from the lowest point of the roof so that rainwater is shed over all lapped joints rather seeping between the sheets.

Insulation manufacturers often recommend an additional 12mm plywood to be provided between the insulation and the membrane.

Fixing to the substrate

Single-ply membranes can be attached to the substrate using any of the following methods;

- Mechanical fixing

This is the most common type of fixing.

The membrane is loosely laid and mechanically fixed through the insulation to the substrate using proprietary metal or plastic screw fastenings.

Single-plys can also be mechanically fixed by heat or chemically welding special membrane coated discs or strips to the deck.

- Adhesive bonding

Adhesive bonding provides a full bond to the insulation or deck. The membrane is rolled into a proprietary adhesive applied directly to the substrate. A few single-plys come with the adhesive already bonded to the membrane.

- Bitumen bonding

Some single-ply membranes are fully compatible with bitumen and can be rolled directly into hot bitumen poured onto the substrate.

- Loose laid and ballasted

This method of fixing is suitable for warm and inverted roofs.

In a warm roof design, the single-ply membrane is laid loose over the insulation. The ballast, in the form of round washed stones, paving slabs or soil and planting (green roof systems), is then laid over the membrane. The weight of the ballast holds the membrane in place.

A polymeric layer should always be provided between the membrane and the ballast to protect the membrane from abrasion.

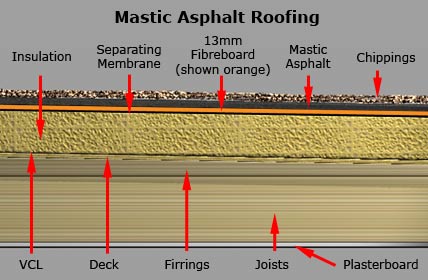

Mastic Asphalt

A mastic asphalt roof gives a seamless covering and can be used on timber, metal and concrete decks. It is not as common as built up felt for small domestic roofs, even though it is known to be more durable and generally performs better as a waterproofing material.

Mastic asphalt is a mixture of asphalt, bitumen and aggregates. Asphalt occurs naturally in asphalt lakes and rock but is more commonly obtained from the process of refining crude oil. Modern mastic asphalt products incorporate polymer which enables an extremely durable and flexible material to be produced.

Mastic asphalt should be laid to the recommendations of BS 8218 Code of Practice for mastic asphalt roofing.

Mastic asphalt is delivered on to the site as solidified blocks and is re-melted before applying to the deck. The number of coats should be appropriate to the waterproofing requirements and anticipated traffic, but will usually be two coats a minimum 20mm thick over an isolating membrane of type 4A black sheathing felt to BS747.

The sheathing felt should be laid loose with 50mm overlaps and will protect the mastic asphalt covering from damage caused by thermal movement of the deck. Insulation manufacturers often specify an additional 13mm fibreboard over the insulation.

The effects of solar radiation on the mastic asphalt can be reduced by rubbing sand into the surface of the topcoat breaking up any build-up of bitumen.

Liquid Applied Coatings

Liquid applied systems are ideal for diy projects and carrying out repairs. They provide a seamless finish with a full bond to substrate and are often a practical option for curved roofs.

Normally, bitumen-based liquid applied systems are emulsified flexible polyurethane systems or synthetic rubber systems. Generic types are defined as ETAs.

Most liquid applied systems are cold-applied, although hot-applied systems are available.

Application

- Apply a primer on a clean dry surface.

- Brush, roll or spray the liquid applied membrane on to the substrate in three or four layers.

- Some form of reinforcement fabric(scrim) to deal with the tensile stresses, either glass fibre or polyester fleece, should be laid loose before the second coat is applied (some types are already fibre-filled and do not require additional reinforcement).

A high standard of workmanship is essential.

No standards exist for this type of system and the manufacturer's guidance should always be followed. Compatibility with insulation, deck etc must be checked. Most types of liquid-applied membranes should not be applied below 5°C.

However, liquid applied membranes do not offer the same durability as some other coverings, with a life expectancy of only around 10 years.

Sheet Metal Roofing

Sheet metal materials commonly used for flat roof covering include aluminium, copper, lead, stainless steel, terne coated stainless steel (TCSS) and zinc.

They are usually in the form of preformed panels with the sheet metal already bonded to a plywood background. The sheets are laid over the supporting structure on a slip layer of polythene to accommodate movement.

Copper is a particularly durable choice of metal but can be expensive. Lead is a more common choice as it is less expensive and can still last 100 years or more.

Sheet membrane should not be laid in temperatures of 5°C or below.

Lead

Lead is specified in codes from Code 3 to 8. The higher the code number, the thicker and more durable the lead will be. Flat roofs will require a minimum of Code 6 lead. Expansion joints known as ‘rolls’ and ‘drips’ must be formed in lead sheeting.

Service Perforations

Air leakage and water ingress should be prevented by sealing around pipes or ducts passing through the roof, for example around soil and vent pipes or roof ventilators. The roofing membrane should be taken up around the pipe or duct and provided with a cover flashing.

Any services through the vapour control layer must also be sealed.

To begin compiling your Building Regulations Specification with one of our Web-Apps, choose either House Extension, New Build, Flat Conversion, Loft Conversion, Garage Conversion, Basement Conversion, Flat Conversion, New Build Flats or Garage Build.